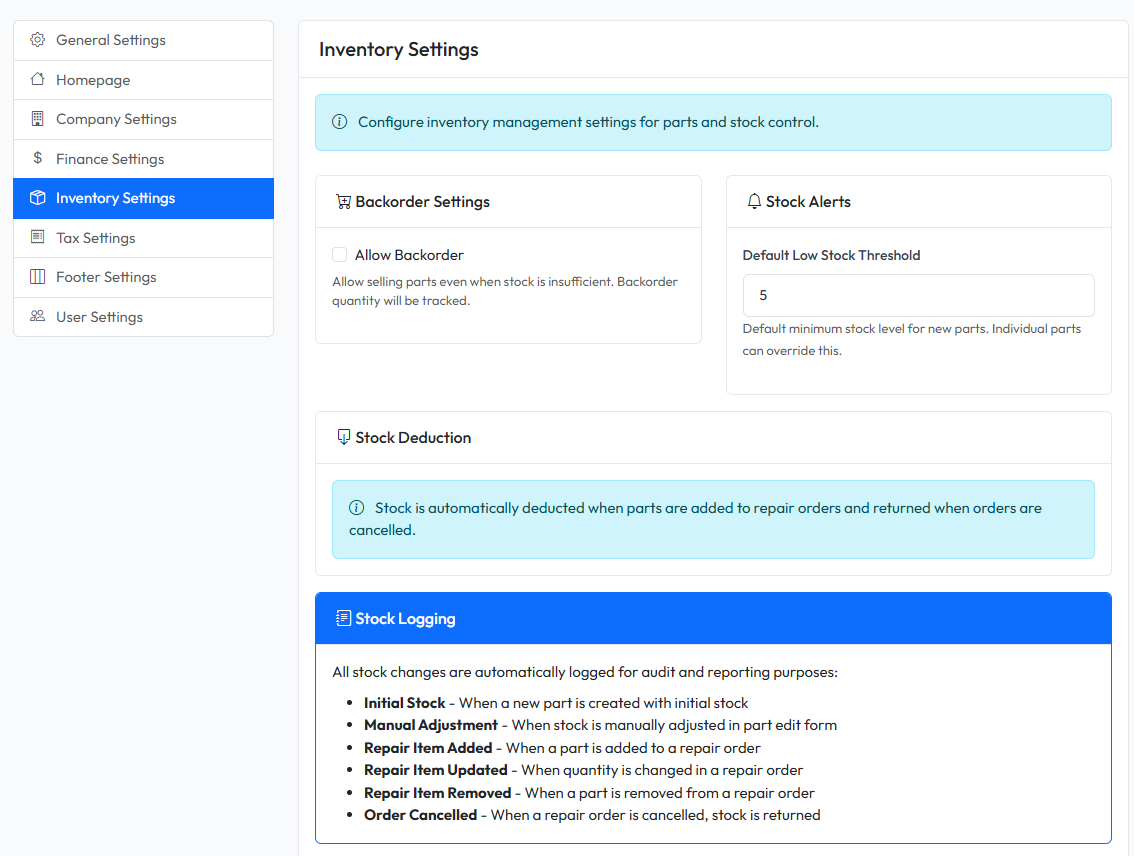

Configure stock management and inventory behavior for your repair shop.

Accessing Inventory Settings

- Navigate to Admin > Settings

- Click on Inventory tab

Available Settings

| Setting | Description |

|---|---|

| Allow Backorder | Allow adding parts to orders even when out of stock |

| Low Stock Threshold | Default quantity level for low stock warnings |

Allow Backorder

When enabled:

- Parts can be added to repair orders even if stock is 0 or insufficient

- Backorder quantity is tracked separately

- Orders can proceed without waiting for stock

When disabled:

- Parts can only be added if sufficient stock is available

- System prevents adding more than available quantity

When to Enable Backorder

- You can order parts quickly from suppliers

- You don't want to delay repair orders

- You track backorders and fulfill them later

When to Disable Backorder

- You want strict stock control

- Parts must be physically available before adding to orders

- You want to prevent overselling

Low Stock Threshold

Set the default quantity level that triggers low stock warnings.

Example: If set to 5, parts with quantity ≤ 5 will be flagged as low stock.

This default applies to new parts. Each part can have its own threshold.

How Stock Works

Automatic Stock Deduction

When you add a part to a repair order:

- System checks available stock

- Stock is automatically deducted

- Stock log entry is created

Stock Return

When you remove a part from an order:

- Stock is automatically returned

- Stock log entry is created

Viewing Stock Logs

Each part has a stock history showing all movements:

- Initial stock

- Deductions for orders

- Returns from cancelled orders

- Manual adjustments

Saving Changes

- Configure settings as needed

- Click Save Settings

- Changes apply to new operations immediately